TPS – S1800

Bending tool quick-change system: In order to get high quality bending for different material, TPS company researched and developed bending tool quick-change system to realize independent quick change for slotting and bending for plate metal material and notching and flanging for flat aluminum material to ensure high accuracy bending for two different processing types.

Functions for processing different material: It can bend aluminum coil max. width 180mm, max. 1mm thickness with slotting, notching and flanging function.

More tool rod bending system: On the basis of alternating double bending bars system, it increases one bending bar for notching of aluminum flat material. It can realize function types changing freely between slotting and bending for flat material and notching, flanging and bending for aluminum flat material. Bending forming degree is greatly increased.

Reel type feeding: The front roller flattening mechanism, it can flatten materials effectively in advance, to avoid jam due to uneven materials.

Alternating clamping feeding mechanism: The alternating clamping feeding mechanism with large torque, high precision and high speed transmission performance is driven with double screw rods and positioning nuts, and controlled by servo motor to ensure real material feeding accuracy to ±0.1mm. It solves problems of slipping and independent of roller pressure feeding type.

Servo motor control notching and flanging mechanism: It uses servo motor to control notching mechanism with characters of smaller size, higher speed, more stable property, without oil contamination and low noise comparing with hydraumatic notching.

Functions for processing different material: It can bend aluminum coil max. width 180mm, max. 1mm thickness with slotting, notching and flanging function.

Software support: DXF/PLT file in,support CAD、TYPE3、CRELDRAW、ILLUSTRATOR,etc.

Features:

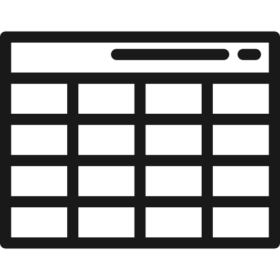

| Power Supply |

AC200V |

| Power |

4.0KW |

| Compressed air |

0.4—0.6MPa |

| Axis Quantities |

5pcs |

| Min. Curving radius |

R7mm |

| Min. Distance between interal and external angles |

4.5mm |

| Start to Bend Distance |

3mm |

| Applied Materials |

Stainless steel,Galvanized sheet,Aluminum Coil(Flanging and notching function only for aluminum) |

| Material Thickness |

0.6-1.0mm |

| Processing Height |

Stainless steel(20-175mm)Aluminum Coil(50-175mm) |

| Material Feeding Method |

Alternating doubel screw rails feeding |

| Notching Method |

C controlled by servo motor |

| Notching Angle |

30°/120° |

| Flanging Method |

Pneumatic flanging for right angle |

| Flanging edge width |

14mm |

| Servo Motor Quantities |

4PCs |

| Step Motor Quantities |

1PC |

| N.W./G.W. |

800Kgs/900kgs |

| Dimension(L W H) |

2290×860×1560mm |

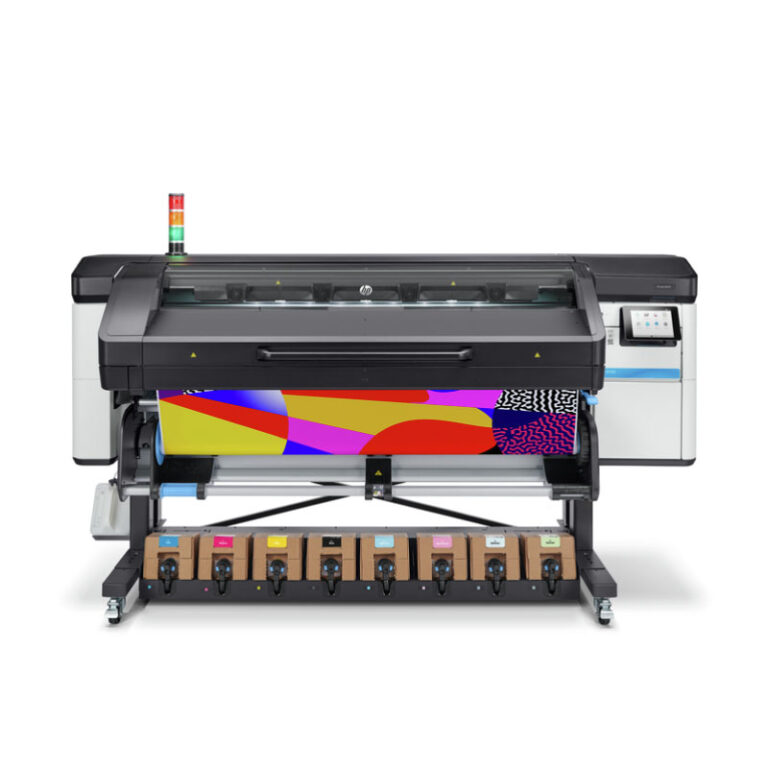

Printing Machines

Printing Machines

Garment Machines

Garment Machines

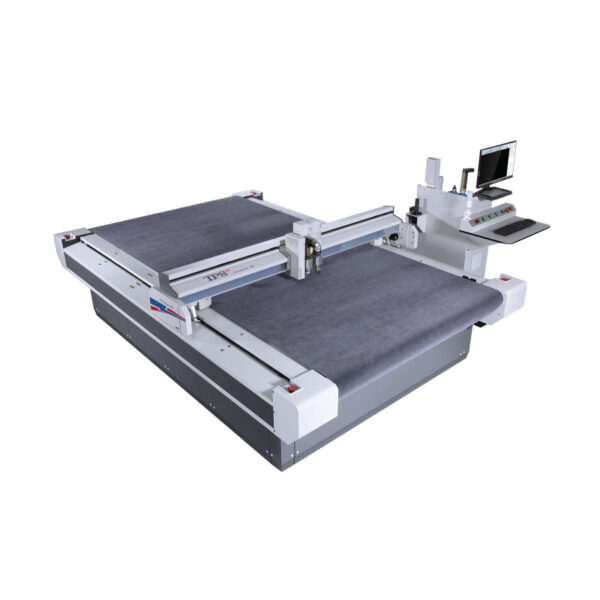

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Bonding

Bonding Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

Wrapping

KSA

KSA Oman

Oman Bahrain

Bahrain Qatar

Qatar Kuwait

Kuwait Kenya

Kenya Pakistan

Pakistan