Product Description:

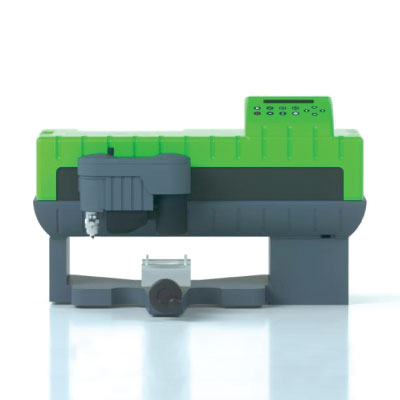

The TS330-1600 is a dye sublimation inkjet printer achieving superb productivity and high image quality through Mimaki printing technology. Designed on a new platform, the printer incorporates improved conveyance mechanism and renewed usability, enabling stable and constant high-quality printing.

The TS330-1600 comes with Mimaki’s high quality Sb411 dye sublimation ink which is known for its rub fastness, durability and colour intensity. Available in a 4, 6 or even 7 colour configuration, supporting light colours and fluorescent colours contributes to the range of applications. Sb411 comes in 2 litre ink packages or high capacity 10kg ink tanks.

This sublimation transfer inkjet printer provides superior image quality and employs Mimaki Weaving Dot Technology (MWDT). MWDT adapts to various printing conditions by changing ink drop placement order, allowing more consistent quality and leading to reduced downtime. To help reduce operating costs, an optional 10kg bulk ink system.

This advanced dye sublimation printing system supports production sizes up to 64″ and has 4, 6, 7, and 8 color configurations. RasterLink7 software (included) TxLink4 textile RIP (available) allow for unmatched productivity.

For even more confidence, Mimaki inks Sb411 are OEKO-TEX® certified. ECO PASSPORT by OEKO-TEX® is a mechanism by which textile chemical suppliers demonstrate that their products are suitable to print skin-friendly clothing and other textiles for end users. This certificate therefore constitutes an important decision-making element when purchasing inks for textile production.

Key Features:

- Next Level Image Quality: A higher image sharpness with more uniform density, while reducing banding even at low pass printing.

- Stable Operation: Throughput is increased while operator mistakes are reduced thanks to new and improved functionalities.

- Versatile Applications: With the variety of inks colours, including fluorescent colours, the range of vivid and eye-catching applications seems endless.

- Scalable Production: With the optional mini jumbo roll unit and the 10KG ink supply unit, you can scale up your production.

- Drive Motor Mounted on the Left and Right Sides: Distributes the load and strengthens winding force.

- V-Shape Cut Function: Fixes the tape at a single point straight against the paper core.

Dual motor take up: increased stability to reduce media walking.

- Cloth wiper: Increases removal of stray ink droplets on the nozzle.

- Mimaki Remote Access (MRA): Allows machine operation via a smartphone or PC.

- Applications: Fashion, Soft Signage, Home and Interior, Sportswear, Promotional Products, Metal Sublimation and more.

Core Technologies:

This printer includes Mimaki Core Technologies that offer the best print quality, maximum productivity and reduced exposure to risks that can delay production. See below list of core technologies that are included in the TS330-1600.

For Continued Productivity:

- Nozzle Check Unit (NCU), to detect missing nozzles

- Nozzle Recovery System (NRS), to replace missing nozzles

- Automatic Cleaning Function, to keep the print head clean

- Mimaki Circulation Technology (MCT), preventing ink sedimentation

- Uninterrupted Ink Supply System (UISS), for uninterrupted ink supply

For Quality Printing:

- Mimaki Advanced Pass System (MAPS4), to reduce banding

- Waveform Control (WFC), for best possible image sharpness

- Variable Dots Technology (VDT), for smoother gradations

- Mimaki Fine Diffusion (MFD), for smoother colours

- Dot Adjustment System (DAS), for stable printing

Technical Specifications:

| Model |

TS330-1600 |

| Print head |

2 drop-on-demand piezoelectric head; stagger arrangement |

| Print resolution |

Y: 300, 600dpi

X: 600dpi, 900 dpi, 1200 |

| Drop size |

Min: 4pl |

| Head height |

Manual adjustment (3.0/3.5/4.0 mm from platen) |

| Compatible inks |

Sb411: BMYK / 4C+F: BMYK FyFp* / 6C: BMYKLbLm / 6C+F: BMYKLbLm FyFp* / 7C: BMYKLkLbLm |

| Ink supply |

2000ml Ink bag

Optional 10kg Tank (BMYK only) |

| Max printing width |

1,610mm |

| Max media width |

1,620mm |

| Media thickness |

1.0mm or less |

| Outside diameter |

250mm or less |

| Inner diameter |

2-inch / 3-inch |

| Roll weight |

45kg or less |

| Interface |

USB2.0 / Ethernet 1000 BASE-T |

| Body weight |

241kg |

| Dimension (WxDxH) |

3,170mm / 1,215mm / 1,305mm |

| Power supply |

1 x Single phase (AC100~120/200~240V +/- 10%, 50/60Hz +/- 1Hz) |

| Power consumption |

Max: 1.44kW or less |

| Safety Standards |

IEC 62368-1 compliant ETLCB, CE (EMC Directive, Low Voltage Directive, Machinery Directive, RoHS Directive) REACH, VCCI Class A, FCC Class AEAC, KC, RCM, UKCA, EnergyStar |

Printing Machines

Printing Machines

Garment Machines

Garment Machines

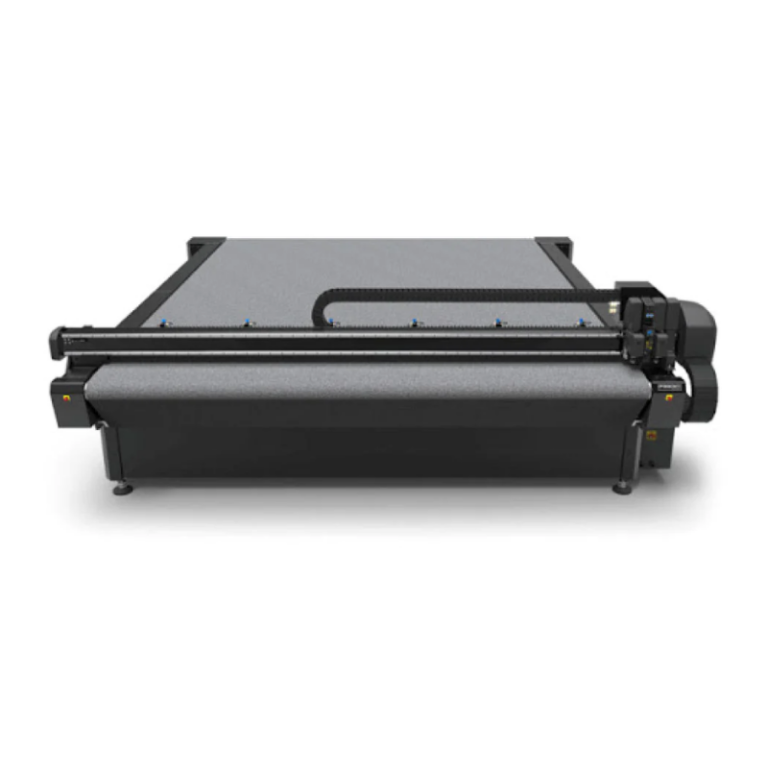

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Bonding

Bonding Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

Wrapping

KSA

KSA Oman

Oman Bahrain

Bahrain Qatar

Qatar Kuwait

Kuwait Kenya

Kenya Pakistan

Pakistan