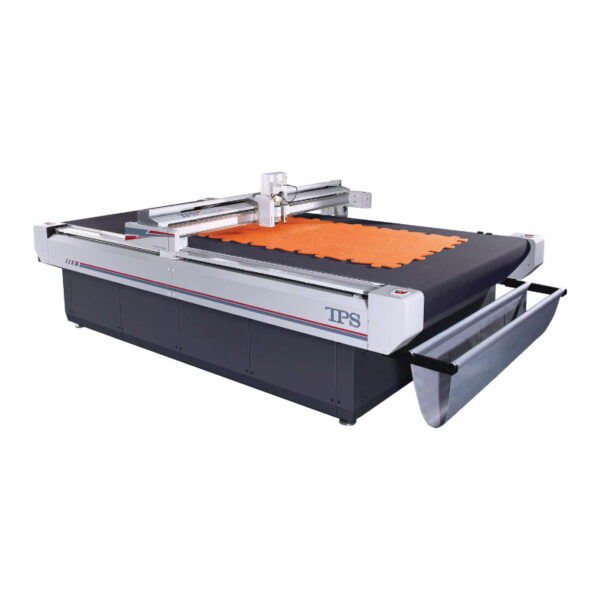

Features of Cutting Machine:

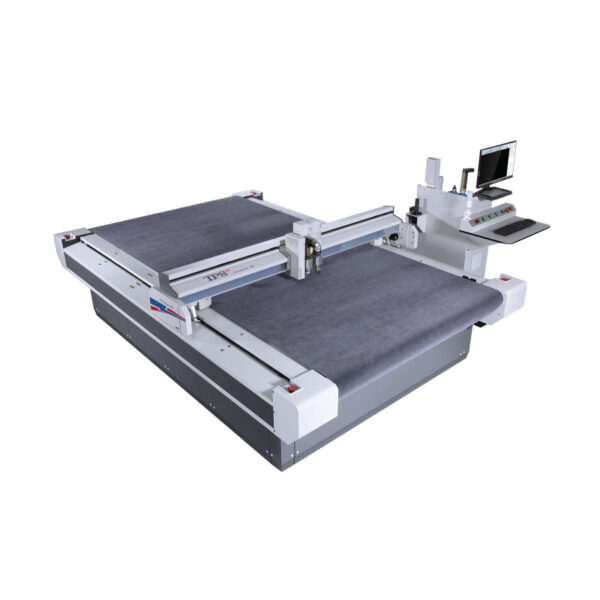

The Strength of our Digital Cutting Machine:

1.Automatic tabletop mapping and height compensation.

2.Automatic detect material thickness.

3.Prevent angle over-cut.

4.Automated tool calibration with fiber laser.

5.Detect two edges of material to find and cut at right position on matching cut at material back.

Equipment:

1. TPS Technology researched and developed CAM software independently which prevents over-cutting at inner angles to recover graphic outline maximally.

2. Intelligent tabletop mapping function: the flatness of tabletop is measured with tabletop mapping by the high-precision height detector, and the tabletop can be height-compensated in real time by the TPS software to ensure perfect cutting result.

3. Realize matching the cut shapes of front and back sides intelligently according to the material edges.

4. Automatic tool calibration: Quick and effortless tool exchange thanks to the fiber laser tool-tip height sensor. It accurately and automatically calibrates the working depth for different tools and greatly contributes to simple operation.

5. Quick-replacement universal modules make simple and efficienct operation and save tool-changing time.

Quick Replacement of Universal tool Module Gets Operation Easy and Convenient:

It can cut acrylic, aluminum composite panel and MDF, etc. in 20mm thickness

Ultra-Frequency Electric Oscillating Tool:

Applicable to cutting all kinds of corrugated, cardboard, KT board, gray board, composite materials, etc

Multi-angle V-Cut Tool:

It can make V-cut angles of 0 , 15 , 22.5 , 30 and 45 for cardboard less than 20mm thickness

Ultra-Frequency Pneumatic Oscillating Tool:

Applicable to cutting seal parts and gaskets material such as asbestos board, asbestos free board, PTFE, rubber board,

fluorine rubber board, silica gel board, graphite board, graphite composite board, etc

Creasing Tool:

Creasing tools are used in packaging industry for making cartoons and boxes of corrugated board, cardboard and pp hollow board,

Wheel Cut Tool:

Applicable to cutting wide variety of flexible material such as UV fabric, carbon fabric, glass Fabric and textiles, etc,

Kiss-cut Tool

Applicable to all kinds of stickers, Vinyl, engineering reflective film, etc

Non- Oscillating Tool:

Applicable to cutting wide variety of flexible material less than 3mm thickness.

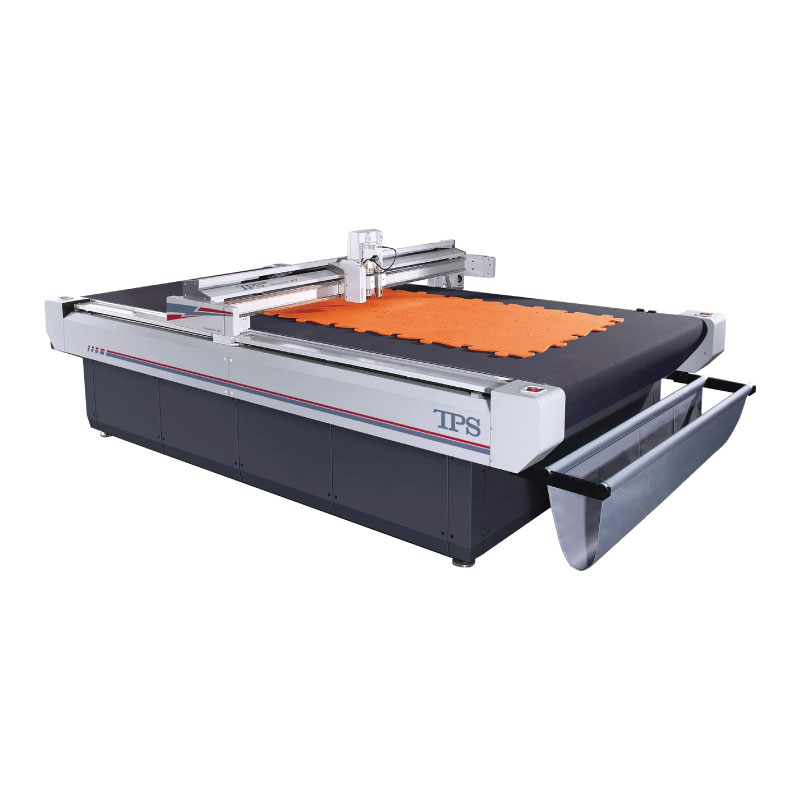

Features:

| Equipment Power |

2.5kw |

| Vacuum pump power |

5.5kw |

| Capacity |

380V 3 phase |

| Work area |

1600x2500mm |

| Max.material size |

1700x3000mm |

| Material max.processing height |

50mm |

| Beam height |

60mm |

| Max.processing speed |

72m/min. |

| Servo motor qty |

7pcs |

| Applied material |

KT Board, Corrugated board, PP paper , Sticker,Fibres,Vinyl , acrylic, MDF,PVC foam board, paper, leather,PU,etc. |

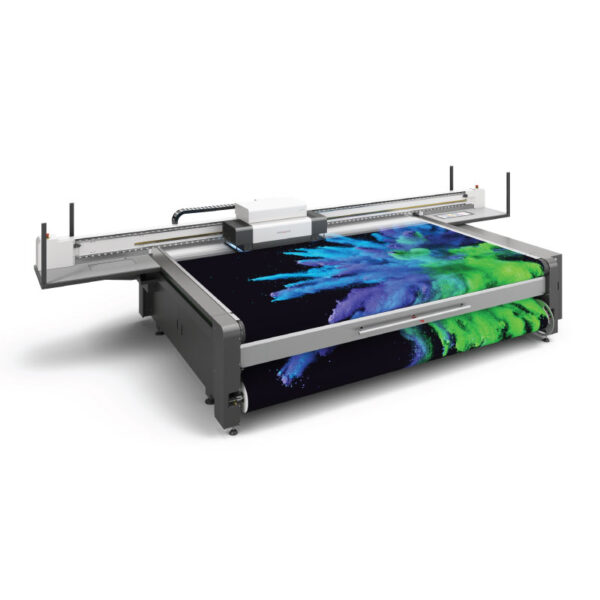

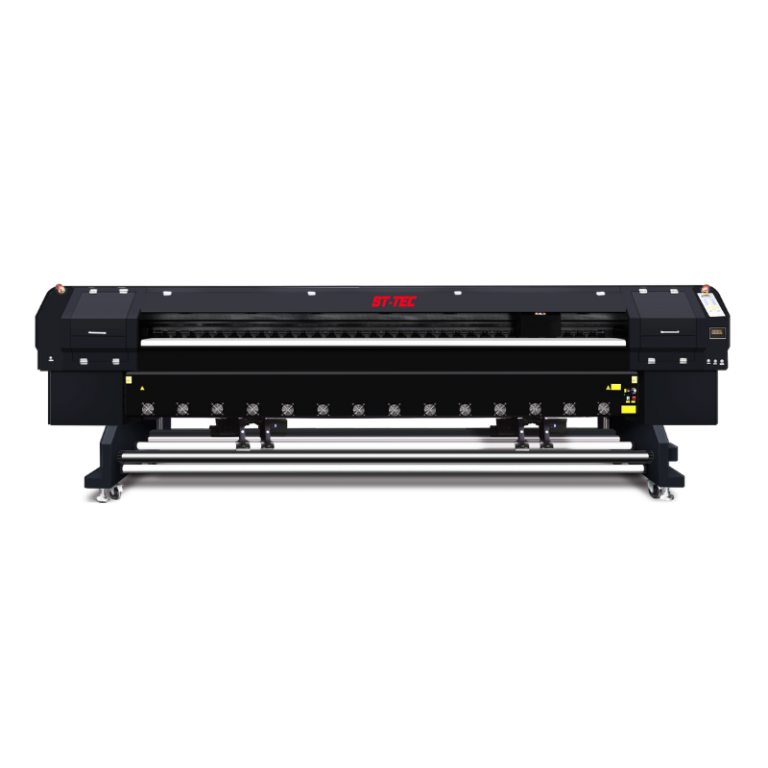

Printing Machines

Printing Machines

Garment Machines

Garment Machines

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Bonding

Bonding Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

Wrapping

KSA

KSA Oman

Oman Bahrain

Bahrain Qatar

Qatar Kuwait

Kuwait Kenya

Kenya Pakistan

Pakistan