Sold out

Printing Machines

Printing Machines

Garment Machines

Garment Machines

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Bonding

Bonding Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

Wrapping800-SIGNTRADE

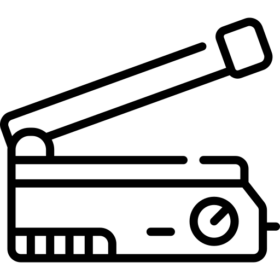

S Class 3 vinyl cutters feature first-class engineering and advanced cutting technology. The new S Class 3 series is crafted to cater to the needs of true professionals who demand nothing short of top-notch performance, pinpoint precision, and unparalleled versatility in their work. With its advanced technology, intuitive software GoSign, durable construction, and time-saving features, they surpass even the most demanding user expectations.

The S Class 3 tangential and drag-knife cutters are the perfect choice for professionals who require performance, precision and versatility. Prepare to elevate your cutting endeavours to new heights of excellence with European craftsmanship. Place your trust in the S Class 3 cutters, and you’ll never look back.

The highly-engineered tangential cutting heads on the S Class 3T Series have a unique motorised knife, allowing the cutters to achieve unparalleled accuracy and precision down to the smallest details. Our True Tangential cutting technology even handles heavy sandblasts, paint masks, and reflective materials.

The Smart Object Sorting feature is designed to select the most optimal starting point for cutting objects, every single time. In addition, the unique Smart Panelling function improves cutting accuracy and simplifies post-processing. When panelling is, e.g., set to 40cm, all objects within this range are cut at once.

The S Class 3 TC models are the most advanced cutters of the S Class 3 Series. Their high-precision cutting head can now carry two tools at once. This allows you to cut and crease or cut and draw without changing tools.

The Optical Positioning System is an automated contour alignment system. The OPOS X sensor technology senses 4 to 128 marks on a wide range of materials. Now, the camera on the S Class 3 Series is more performant with even faster recognition abilities.

Discover improved ease of use with a blue, green, and red-lighted status bar. Additionally, swiftly identify adjustable components by their blue colour. This is complemented by a strategically placed tool tray at the back for efficient operation. The S Class 3 is also designed with a focus on ergonomics and simplicity in usage.

The user-friendly software GoSign is your first choice cutting software, allowing you to manage your preferred workflow with great flexibility. Settings and action sets can be created and tailored according to your specific cutting jobs at any given time.

The media roll on the cutter can now handle a diameter of 20 cm and supports a roll weight of at least 45 kg. This improvement is highly beneficial for print and cut applications, including laminated vinyl.

After finishing a job, the system will roll up the artwork neatly and prepare the machine for the next one. The integrated panelling feature splits long-length runs into shorter consecutive tasks, allowing to cut complete rolls unattended and deliver the output nicely rolled-up.

With G-Performance, you can boost the production on the S Class 3 roll cutters by up to 40%. Its impact is especially noticeable on a faster reading of the registration marks and when cutting wider substrates.

| Model | S3 160 | ||||||

| Dimensions | 225 x 69 x 111 cm | ||||||

| Media Width | 17 to 168 cm | ||||||

| Max. Working Width Oversized Mode* | 158 cm x 50 m |

|

|||||

| ‘Oversized’ mode allows a wider cutting area : +/- 7 cm* | |||||||

| Pinch Rollers | 4 | ||||||

| Alignment Type |

|

||||||

| Tracking Performance | Within +/- 0.1 mm on plots:

|

||||||

| Media Thickness | 0.05 mm to 0.25 mm / Up to 0.8 mm with sandblast drag knife / Up to 1.2 mm with sandblast tangential knife | ||||||

| Accuracy | 0.2% of move or 0.25 mm, whichever is greater | ||||||

| Speed | Up to 1440 mm/s diagonal | ||||||

| Acceleration | Up to 4.2 G diagonal | ||||||

| Knife Pressure | Drag Knife: Up to 400 grams / Tangential Knife: Up to 1000 grams | ||||||

| Extra Pen or Creaser Pressure | Up to 1000 grams | ||||||

| Other Features | FlexCut (cutting through) | ||||||

| Connectivity | Ethernet, USB, WIFI | ||||||

| Power Requirements | 100-120 / 220-240 VAC, 50/60 Hz, 85 VA maximum | ||||||

| Included Software | Summa GoSign Software, Summa Cutter Control / Plug-in: Illustrator, CorelDraw, MacSign | ||||||

| Cutting Technology | Drag Knife / Tangential knife | ||||||

| * In ‘Oversized’ mode the tracking performance is no longer guaranteed. | |||||||

| Brand | |

|---|---|

| Product Type | |

| Function | |

| Classification |

Payment Methods:

S Class 3 vinyl cutters feature first-class engineering and advanced cutting technology. The new S Class 3 series is crafted to cater to the needs of true professionals who demand nothing short of top-notch performance, pinpoint precision, and unparalleled versatility in their work. With its advanced technology, intuitive software GoSign, durable construction, and time-saving features, they surpass even the most demanding user expectations.

The S Class 3 tangential and drag-knife cutters are the perfect choice for professionals who require performance, precision and versatility. Prepare to elevate your cutting endeavours to new heights of excellence with European craftsmanship. Place your trust in the S Class 3 cutters, and you’ll never look back.

The highly-engineered tangential cutting heads on the S Class 3T Series have a unique motorised knife, allowing the cutters to achieve unparalleled accuracy and precision down to the smallest details. Our True Tangential cutting technology even handles heavy sandblasts, paint masks, and reflective materials.

The Smart Object Sorting feature is designed to select the most optimal starting point for cutting objects, every single time. In addition, the unique Smart Panelling function improves cutting accuracy and simplifies post-processing. When panelling is, e.g., set to 40cm, all objects within this range are cut at once.

The S Class 3 TC models are the most advanced cutters of the S Class 3 Series. Their high-precision cutting head can now carry two tools at once. This allows you to cut and crease or cut and draw without changing tools.

The Optical Positioning System is an automated contour alignment system. The OPOS X sensor technology senses 4 to 128 marks on a wide range of materials. Now, the camera on the S Class 3 Series is more performant with even faster recognition abilities.

Discover improved ease of use with a blue, green, and red-lighted status bar. Additionally, swiftly identify adjustable components by their blue colour. This is complemented by a strategically placed tool tray at the back for efficient operation. The S Class 3 is also designed with a focus on ergonomics and simplicity in usage.

The user-friendly software GoSign is your first choice cutting software, allowing you to manage your preferred workflow with great flexibility. Settings and action sets can be created and tailored according to your specific cutting jobs at any given time.

The media roll on the cutter can now handle a diameter of 20 cm and supports a roll weight of at least 45 kg. This improvement is highly beneficial for print and cut applications, including laminated vinyl.

After finishing a job, the system will roll up the artwork neatly and prepare the machine for the next one. The integrated panelling feature splits long-length runs into shorter consecutive tasks, allowing to cut complete rolls unattended and deliver the output nicely rolled-up.

With G-Performance, you can boost the production on the S Class 3 roll cutters by up to 40%. Its impact is especially noticeable on a faster reading of the registration marks and when cutting wider substrates.

| Model | S3 160 | ||||||

| Dimensions | 225 x 69 x 111 cm | ||||||

| Media Width | 17 to 168 cm | ||||||

| Max. Working Width Oversized Mode* | 158 cm x 50 m |

|

|||||

| ‘Oversized’ mode allows a wider cutting area : +/- 7 cm* | |||||||

| Pinch Rollers | 4 | ||||||

| Alignment Type |

|

||||||

| Tracking Performance | Within +/- 0.1 mm on plots:

|

||||||

| Media Thickness | 0.05 mm to 0.25 mm / Up to 0.8 mm with sandblast drag knife / Up to 1.2 mm with sandblast tangential knife | ||||||

| Accuracy | 0.2% of move or 0.25 mm, whichever is greater | ||||||

| Speed | Up to 1440 mm/s diagonal | ||||||

| Acceleration | Up to 4.2 G diagonal | ||||||

| Knife Pressure | Drag Knife: Up to 400 grams / Tangential Knife: Up to 1000 grams | ||||||

| Extra Pen or Creaser Pressure | Up to 1000 grams | ||||||

| Other Features | FlexCut (cutting through) | ||||||

| Connectivity | Ethernet, USB, WIFI | ||||||

| Power Requirements | 100-120 / 220-240 VAC, 50/60 Hz, 85 VA maximum | ||||||

| Included Software | Summa GoSign Software, Summa Cutter Control / Plug-in: Illustrator, CorelDraw, MacSign | ||||||

| Cutting Technology | Drag Knife / Tangential knife | ||||||

| * In ‘Oversized’ mode the tracking performance is no longer guaranteed. | |||||||

| Brand | |

|---|---|

| Product Type | |

| Function | |

| Classification |

Printing Machines

Printing Machines

Garment Machines

Garment Machines

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Laminate

Laminate Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

Wrapping Printing Machines

Printing Machines

Garment Machines

Garment Machines

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Laminate

Laminate Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

WrappingNo account yet?

Create an Account

Out of stock

Company Overview:

Signtrade, with over 30 years of experience, has firmly established itself as a global leader in the signage industry, consistently driving innovation and technological advancement. Our unwavering commitment to excellence has earned us acclaim not only in the MENASA region but also on the international stage. As the foremost service provider in the region, we offer tailored, region-specific solutions, thoughtfully curated with state-of-the-art technology. We take immense pride in delivering unparalleled sales and technical services through our extensive sales network. At the heart of our achievements is our entrepreneurial team, whose dedication is pivotal to our enduring success.

Job Description:

As a Service Engineer for Large Format Printing Machines at Signtrade, your primary responsibility will be to install, repair, and service a wide range of Wide Format Equipment from top manufacturers. Working within a designated geographic territory, you will be dispatched to various job assignments based on the product and your level of experience. You will receive comprehensive training to make necessary mechanical or electrical repairs and provide preventive maintenance on all machines serviced.

Key Responsibilities:

Requirements:

How to Apply:

If you are a passionate, dedicated and technically proficient with the experience in Large Format Printing Machines, please send your resume and cover letter to [email protected].

Company Overview:

Signtrade, with over 30 years of experience, has firmly established itself as a global leader in the signage industry, consistently driving innovation and technological advancement. Our unwavering commitment to excellence has earned us acclaim not only in the MENASA region but also on the international stage. As the foremost service provider in the region, we offer tailored, region-specific solutions, thoughtfully curated with state-of-the-art technology. We take immense pride in delivering unparalleled sales and technical services through our extensive sales network. At the heart of our achievements is our entrepreneurial team, whose dedication is pivotal to our enduring success.

Job Description:

As a Color Management Profiler at Signtrade, you will be a critical contributor to ensuring accurate and consistent color reproduction for our projects. Your main responsibility will be to operate and manage the Barbieri Spectrophotometer, with the goal of calibrating and maintaining color profiles for various output devices, including printers and displays. You will closely collaborate with our production and design teams to attain the highest standards of color accuracy.

Key Responsibilities:

Qualifications:

How to Apply:

If you are a passionate color management professional with experience operating the Barbieri Spectrophotometer and are eager to contribute to a creative and dynamic team, please send your resume and cover letter to [email protected].