Sold out

Printing Machines

Printing Machines

Garment Machines

Garment Machines

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Bonding

Bonding Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

Wrapping800-SIGNTRADE

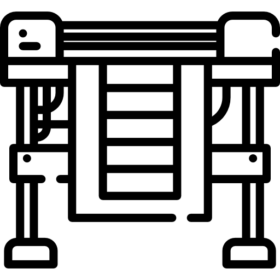

Summa’s professional Flatbed Cutting System is an innovative solution for producing a broad variety of signage, displays, samples, packaging applications, and more.

With an ever-increasing arsenal of tools and optional add-ons, the F Series flatbed cutting system is the breakthrough cutting solution you’ve been dreaming about.

Your range of applications is endless with the F Series. Enjoy industry-leading features and optional add-ons.

The software GoProduce is developed to handle jobs easy and efficiently. The modern interface with improved navigation enables users to find and operate functions as quickly and intuitively as possible.

The multifunctional head can hold up to three modules at one time. The central unit houses a positioning laser and an integrated camera system for fast and accurate contour-cutting mark recognition.

Offering a vertical force of 10 kg and corresponding to a wide range of matching tools. Each tool has a barcode identifier, ensuring automatic recognition and parameter settings.

The advanced Safety System, delivered with all F Series models, guarantees a safe work environment and is compliant to worldwide health and safety requirements. Thanks to the placement of the system on the top beam, the F Series can be accessed easily, which results in higher production efficiency.

The barcode automatically identifies the job to obtain the necessary cutting data from the computer. The built-in camera scans the job automatically or by a hand scanner, depending on the selected workflow.

The ADC automatically sets the knife depth and the orientation of the tool. The tip of the knife or bit is measured accurately and the down position of the tool is set to table’s level, guaranteeing a flawless cut. Both the ADC left and ADC right is included with every new F Series flatbed cutter.

The conveyor extension, optional on the F1612 flatbed cutter, processes cut designs that are much larger than the actual cutting area. While the machine cuts the next part, the first cutout parts can be removed safely at the extended front.

Increase the performance of your F Series flatbed system with almost 40%. Advantages include faster up, down and turning movements of the cutting head, which will be most remarkable when using the Kiss-cutting tool.

The optional Heavy-Duty Roll Support allows a straight throughput of print rolls onto the wide-format flatbed sizes, F1832, F3220 and F3232. For the processing of heavy banner material and light to non-stretchable wide textile rolls, this roll support will facilitate the operator’s life considerably.

| Model | F1832 |

| Dimensions | 279 x 422 x 122 cm |

| Material width | Up to 190 cm |

| Work zone | 184 x 320 cm |

| Vacuum | 2 x 2.2 kW (50Hz) / 2 x 2.55 kW (60Hz) |

| Vacuum zones | 8 zones (2 lines x 4 columns) |

| Requirements | Standard: 3 x 400V + N, 50Hz, max 30A |

| Or: 3 x 208V + N, 60Hz, max 30A | |

| Or: 3 x 230V, 50Hz, max 20A | |

| Standard solution includes: | • F Series flatbed system |

| • Conveyor system with pneumatic media clamps and roll support | |

| • Security Pack | |

| • Camera system | |

| • Axis Control software | |

| • Drag module | |

| • ADC left & right | |

| • GoProduce software | |

| • Speed: up to1000 mm/sec | |

| • Acceleration: up to 1G |

| Brand | |

|---|---|

| Product Type | |

| Function | |

| Classification |

Payment Methods:

Summa’s professional Flatbed Cutting System is an innovative solution for producing a broad variety of signage, displays, samples, packaging applications, and more.

With an ever-increasing arsenal of tools and optional add-ons, the F Series flatbed cutting system is the breakthrough cutting solution you’ve been dreaming about.

Your range of applications is endless with the F Series. Enjoy industry-leading features and optional add-ons.

The software GoProduce is developed to handle jobs easy and efficiently. The modern interface with improved navigation enables users to find and operate functions as quickly and intuitively as possible.

The multifunctional head can hold up to three modules at one time. The central unit houses a positioning laser and an integrated camera system for fast and accurate contour-cutting mark recognition.

Offering a vertical force of 10 kg and corresponding to a wide range of matching tools. Each tool has a barcode identifier, ensuring automatic recognition and parameter settings.

The advanced Safety System, delivered with all F Series models, guarantees a safe work environment and is compliant to worldwide health and safety requirements. Thanks to the placement of the system on the top beam, the F Series can be accessed easily, which results in higher production efficiency.

The barcode automatically identifies the job to obtain the necessary cutting data from the computer. The built-in camera scans the job automatically or by a hand scanner, depending on the selected workflow.

The ADC automatically sets the knife depth and the orientation of the tool. The tip of the knife or bit is measured accurately and the down position of the tool is set to table’s level, guaranteeing a flawless cut. Both the ADC left and ADC right is included with every new F Series flatbed cutter.

The conveyor extension, optional on the F1612 flatbed cutter, processes cut designs that are much larger than the actual cutting area. While the machine cuts the next part, the first cutout parts can be removed safely at the extended front.

Increase the performance of your F Series flatbed system with almost 40%. Advantages include faster up, down and turning movements of the cutting head, which will be most remarkable when using the Kiss-cutting tool.

The optional Heavy-Duty Roll Support allows a straight throughput of print rolls onto the wide-format flatbed sizes, F1832, F3220 and F3232. For the processing of heavy banner material and light to non-stretchable wide textile rolls, this roll support will facilitate the operator’s life considerably.

| Model | F1832 |

| Dimensions | 279 x 422 x 122 cm |

| Material width | Up to 190 cm |

| Work zone | 184 x 320 cm |

| Vacuum | 2 x 2.2 kW (50Hz) / 2 x 2.55 kW (60Hz) |

| Vacuum zones | 8 zones (2 lines x 4 columns) |

| Requirements | Standard: 3 x 400V + N, 50Hz, max 30A |

| Or: 3 x 208V + N, 60Hz, max 30A | |

| Or: 3 x 230V, 50Hz, max 20A | |

| Standard solution includes: | • F Series flatbed system |

| • Conveyor system with pneumatic media clamps and roll support | |

| • Security Pack | |

| • Camera system | |

| • Axis Control software | |

| • Drag module | |

| • ADC left & right | |

| • GoProduce software | |

| • Speed: up to1000 mm/sec | |

| • Acceleration: up to 1G |

| Brand | |

|---|---|

| Product Type | |

| Function | |

| Classification |

Printing Machines

Printing Machines

Garment Machines

Garment Machines

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Laminate

Laminate Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

Wrapping Printing Machines

Printing Machines

Garment Machines

Garment Machines

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Laminate

Laminate Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

WrappingNo account yet?

Create an Account

Out of stock

Company Overview:

Signtrade, with over 30 years of experience, has firmly established itself as a global leader in the signage industry, consistently driving innovation and technological advancement. Our unwavering commitment to excellence has earned us acclaim not only in the MENASA region but also on the international stage. As the foremost service provider in the region, we offer tailored, region-specific solutions, thoughtfully curated with state-of-the-art technology. We take immense pride in delivering unparalleled sales and technical services through our extensive sales network. At the heart of our achievements is our entrepreneurial team, whose dedication is pivotal to our enduring success.

Job Description:

As a Service Engineer for Large Format Printing Machines at Signtrade, your primary responsibility will be to install, repair, and service a wide range of Wide Format Equipment from top manufacturers. Working within a designated geographic territory, you will be dispatched to various job assignments based on the product and your level of experience. You will receive comprehensive training to make necessary mechanical or electrical repairs and provide preventive maintenance on all machines serviced.

Key Responsibilities:

Requirements:

How to Apply:

If you are a passionate, dedicated and technically proficient with the experience in Large Format Printing Machines, please send your resume and cover letter to [email protected].

Company Overview:

Signtrade, with over 30 years of experience, has firmly established itself as a global leader in the signage industry, consistently driving innovation and technological advancement. Our unwavering commitment to excellence has earned us acclaim not only in the MENASA region but also on the international stage. As the foremost service provider in the region, we offer tailored, region-specific solutions, thoughtfully curated with state-of-the-art technology. We take immense pride in delivering unparalleled sales and technical services through our extensive sales network. At the heart of our achievements is our entrepreneurial team, whose dedication is pivotal to our enduring success.

Job Description:

As a Color Management Profiler at Signtrade, you will be a critical contributor to ensuring accurate and consistent color reproduction for our projects. Your main responsibility will be to operate and manage the Barbieri Spectrophotometer, with the goal of calibrating and maintaining color profiles for various output devices, including printers and displays. You will closely collaborate with our production and design teams to attain the highest standards of color accuracy.

Key Responsibilities:

Qualifications:

How to Apply:

If you are a passionate color management professional with experience operating the Barbieri Spectrophotometer and are eager to contribute to a creative and dynamic team, please send your resume and cover letter to [email protected].