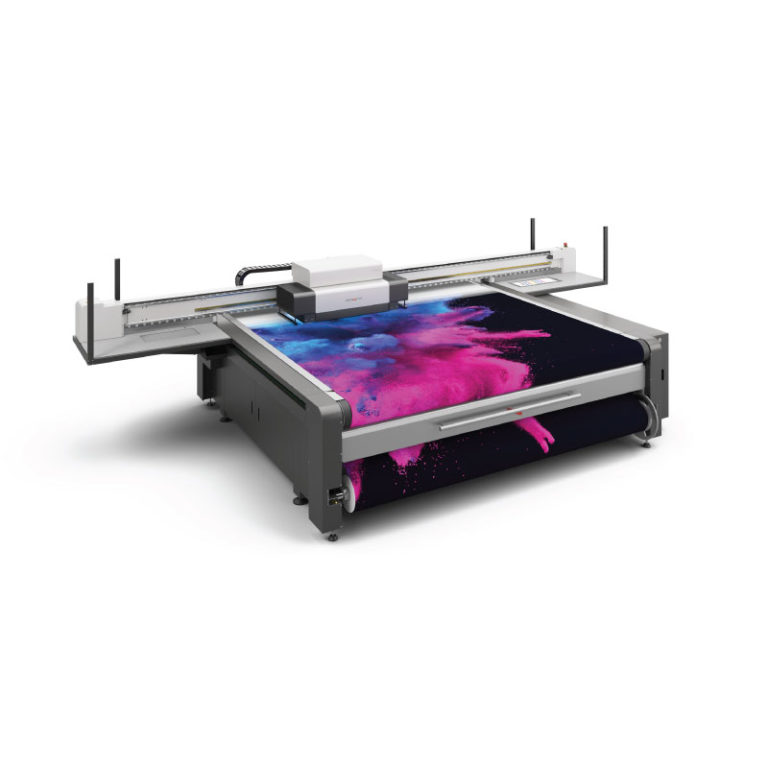

ST-TEC DTF-650T Direct to Film Machine (DTF) – the ultimate solution for revolutionizing your printing experience. This state-of-the-art DTF Printer, proudly presented by the world-renowned brand ST-TEC, brings unmatched quality, speed, and versatility to your printing tasks.

Experience the power of innovation with the DTF Printer’s cutting-edge features. Equipped with 4pcs Epson original 13200 heads, it guarantees exceptional print accuracy and clarity, making your designs come to life in vibrant hues.

No more worries about white ink clogging! The DTF Printer incorporates a specially designed stirring and circulation system for the white ink, ensuring a seamless printing process every time.

Durable and reliable, the printer’s robust body is complemented by advanced functionalities, including up and down capping, HIWIN guide rail, and print heads anti-crash system, ensuring smooth operations and minimized downtime.

Take your PET film printing to new heights with the back and front heaters, specially integrated for flawless PET film printing results. Plus, with the secondary ink tank for color ink, you can print without interruption, confident that your ink supply remains continuous.

Time is of the essence, and we understand the need for efficiency. That’s why our DTF Printer supports color + white printing simultaneously, perfect for fast PET film transfer applications, streamlining your workflow like never before.

But that’s not all – complement your DTF Printer with the Coater Dryer Machine, a game-changer in the world of printing. Benefit from lightning-fast printing speeds, thanks to the longer dryer parts that ensure quick drying without compromising quality.

Pre-dry your ink before powdering with the top heater and front heating plate, resulting in impeccably smooth and vivid prints that leave a lasting impression.

With the Coater Dryer Machine’s powder amount control sensor, excess powder usage becomes a thing of the past. Say goodbye to waste, as the motor automatically stops powdering once the optimal level is reached.

Join the future of printing technology with the ST-TEC DTF-650T Direct to Film Machine, where precision, efficiency, and innovation converge to bring your creative visions to life. Elevate your printing game with ST-TEC today.

Technical Specification:

DTF Printer:

Printing Machines

Printing Machines

Garment Machines

Garment Machines

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

Laser Machines

Laser Machines

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Bonding

Bonding Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

Wrapping

KSA

KSA Oman

Oman Bahrain

Bahrain Qatar

Qatar Kuwait

Kuwait Kenya

Kenya Pakistan

Pakistan