Product Description:

With the strong heritage of its predecessor, the CJV-330-160 solvent printer has been designed and developed from the ground up, featuring many new features and innovations, further improving both image quality and productivity, setting the new benchmark in Sign graphics.

The CJV 330-160 solvent printer can be configured with different ink-sets to be based on application requirements. Mimaki’s SS21 Mild solvent ink-type, available in a 4-colour (productivity), 6-colour (transparent media) and 8-colour (widest colour gamut) configuration, is known for its excellent quality, weatherability and rub-fastness. Mimaki’s BS4 Mild solvent ink-type, only available in a 4-colour configuration (productivity), is known for its fast drying, less odour and cost effectiveness.With this new printer, Mimaki offers a solution for any application requirement, making the CJV-330-160 a versatile solution.

For even more confidence, CJV330-160 and Mimaki’s SS21 and BS4 inks are GREENGUARD GOLD certified products that meet the rigorous standards for low emission of volatile organic compounds (VOCs) and ensures that a product is acceptable for use in environments such as schools and healthcare facilities without polluting the indoor air quality.

Key Features:

- Next level Image Quality: Higher image sharpness and more uniform density, while reducing banding even at low pass printing.

- Media Changer: Space saving system that can hold three rolls of media and fast media change by a single operator.

- XY Slitter: Inline sheet-fed cutting system that reduces post-processing.

- Improved Operation: Throughput is increased while operator mistakes are reduced, thanks to new and improved functionalities.

- Designed to Produce a Wide Range of Materials and Applications: Stickers & Labels, Vehicle Graphics, Window Decorations, Banners & Posters, Heat Transfer Vinyl, Backlit, Wallpaper, Floor stickers and more.

Core Technologies:

This printer includes Mimaki Core Technologies that offer the best print quality, maximum productivity and reduced exposure to risks that can delay production. See below list of core technologies that are included in the CJV330-160 solvent printer.

For Continued Productivity:

- Nozzle Check Unit (NCU), to detect missing nozzles

- Nozzle Recovery System (NRS), to replace missing nozzles

Automatic Cleaning Function, to keep the print head clean

- Mimaki Circulation Technology (MCT), preventing ink sedimentation

- Uninterrupted Ink Supply System (UISS), for uninterrupted ink supply

For Quality Printing:

- Mimaki Advanced Pass System (MAPS4), to reduce banding

- Waveform Control (WFC), for best possible image sharpness

- Variable Dots Technology (VDT), for smoother gradations

- Mimaki Fine Diffusion (MFD), for smoother colour tones

- Dot Adjustment System (DAS), for stable printing

- Mimaki Intelligent Heater (MIH), for consistent image quality

For Superior Cutting:*

- ID Cut, to increase productivity

- Crop Mark Detection, for a high accurate cut

- Half Cut, to reduce manual labour

- Over Cut, for easy weeding

- Corner Cut, for the perfect contour cut

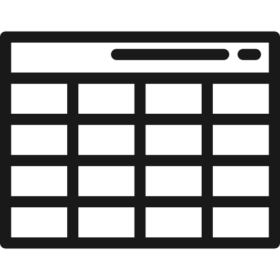

Technical Specifications:

(C)JV330-160 Printer Specifications

| Item |

JV330-160, CJV330-160 |

| Print head |

2 drop-on-demand piezoelectric head; stagger arrangement |

| Print resolution |

Y: 600dpi, 800dpi, 1200dpi;

X: 600dpi, 900dpi, 1200dpi |

| Drop size |

Min: 3pl |

| Head height |

Manual adjustment (2.0/2.5/3.0 mm from platen) |

| Compatible inks |

SS21 – 4C: CMYK / 6C+SP: CMYKLcLmW / 8C: CMYKLcLmLkOr

BS4 – 4C: CMYK |

| Ink supply |

Colour: 2000ml Ink bag

White: 500ml ink bag |

| Max printing width |

1,610mm |

| Max media width |

1,620mm |

| Media thickness |

1.0mm or less |

| Outside diameter |

250mm or less |

| Inner diameter |

2-inch / 3-inch |

| Roll weight |

1 Roll: 45kg or less

3 Rolls: total 90kg or less |

| Interface |

USB2.0 / Ethernet 1000 BASE-T |

| Body weight |

368kg |

| Dimension (WxDxH) |

3,170 / 1,215 / 1,305mm |

| Power supply |

2 x Single phase (AC100~120/200~240V +/- 10%, 50/60Hz +/- 1Hz) |

| Power consumption |

Max: 2 x 1.44kW or less; Std: 2 x 750W; Min: 4,5W |

| Safety Standards |

IEC 62368-1 compliant ETLCB, CE (EMC Directive, Low Voltage Directive, Machinery Directive, RoHS Directive) REACH, VCCI Class A, FCC Class AEAC, KC, RCM, UKCA, EnergyStar |

CJV330-160 Cutting Specifications

| Item |

CJV330-160 |

| Cutting speed*1 |

300mm/s or less |

| Acceleration |

0.5G or less |

| Cutting pressure |

10~450gf |

| Cutter response time |

10 times/sec |

| Repetition accuracy |

±0.2mm |

| Receive buffer memory |

30MB |

| Command |

MGL-Iic |

| Program step |

25μm |

*1: The maximum speed may be limited, depending on the size of a used medium. In addition, the cutting section does not operate with both speed and acceleration being at the maximum

Printing Machines

Printing Machines

Garment Machines

Garment Machines

Cutting Machines

Cutting Machines

Heating Machines

Heating Machines

Bending Machines

Bending Machines

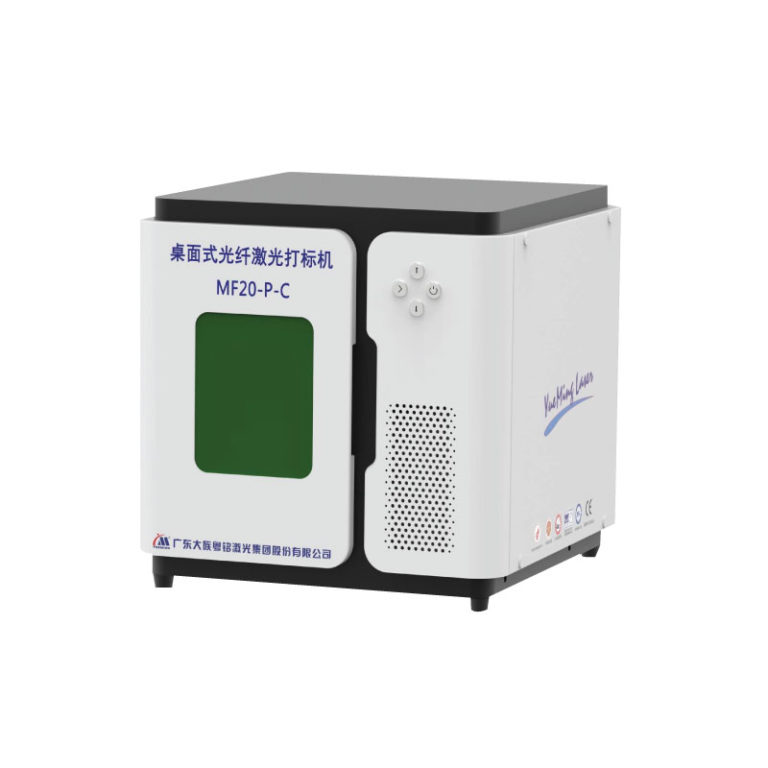

Laser Machines

Laser Machines

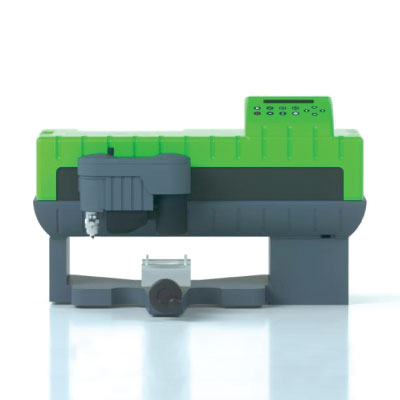

Router Machines

Router Machines

Finishing Machines

Finishing Machines

Printing Media

Printing Media

Acrylic Sheets

Acrylic Sheets

LED Lights

LED Lights

Modular Signs

Modular Signs

Display

Display

Architectural Design

Architectural Design Backlit

Backlit Bonding

Bonding Branding

Branding Cladding

Cladding Color Change

Color Change Cut-outs

Cut-outs Display Stands

Display Stands Divider Making

Divider Making Engraving

Engraving Flex Face

Flex Face Garment Decoration

Garment Decoration Gifts

Gifts Glow In The Dark – Signage

Glow In The Dark – Signage Indoor Signage

Indoor Signage Interior Decoration

Interior Decoration Interior Decoration and Partition

Interior Decoration and Partition Letter Cutting

Letter Cutting Mirror Effect

Mirror Effect Partition

Partition Plotter Cutting

Plotter Cutting Printing

Printing Printing Media

Printing Media Printing Textile Media

Printing Textile Media Promotional Gifts

Promotional Gifts Raised Pavement Marker

Raised Pavement Marker Reflective Branding

Reflective Branding Reflective Protection Film

Reflective Protection Film Road Directional Signage Work Zone

Road Directional Signage Work Zone Screen Printing On Reflective Sheets

Screen Printing On Reflective Sheets Signboard

Signboard Signboards

Signboards ST-Display

ST-Display Stands

Stands Tables

Tables Tables and Stands

Tables and Stands Tables, Stands

Tables, Stands Temporary Road Marking Tape

Temporary Road Marking Tape Transclucent Films

Transclucent Films Tshirt Printing

Tshirt Printing Uniforms

Uniforms Vinyl Pasting

Vinyl Pasting Visibility Marking Tape

Visibility Marking Tape Way Finding / Road Directional Signage

Way Finding / Road Directional Signage Wrapping

Wrapping

KSA

KSA Oman

Oman Bahrain

Bahrain Qatar

Qatar Kuwait

Kuwait Kenya

Kenya Pakistan

Pakistan